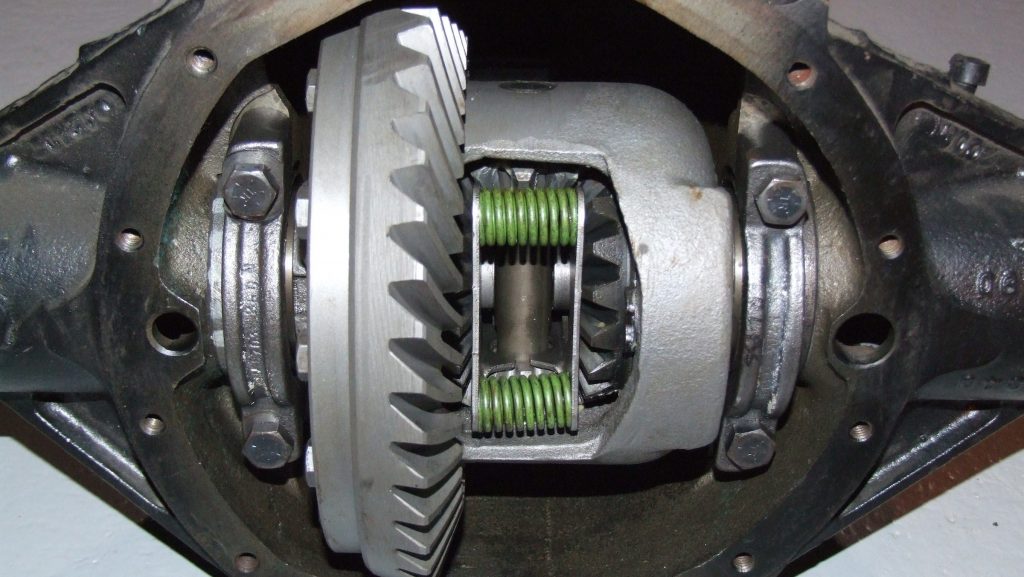

A properly functioning differential and gearbox are essential components of any vehicle, ensuring that power is transferred from the engine to the wheels and that the vehicle can move smoothly and efficiently. However, maintaining these components can be a challenge, particularly when it comes to fitting the gripper plate differential and setting the gearbox bearing preload.

In September of this year, Pinderwagen owner John Smith noticed that something was wrong with his car's differential. Although he suspected that the issue was related to the gripper plate differential, which he had installed some time ago, he was unable to find the time to remove the gearbox for inspection.

Upon finally stripping the gearbox, John found that the problem was indeed related to the gripper plate differential. However, it was not the fault of the differential itself, but rather the way in which it had been installed. Specifically, the gearbox bearing preload had not been set correctly, which had caused excessive wear and damage to the differential and other components.

This experience highlights the importance of proper differential fitting and gearbox bearing preload setting. When installing a gripper plate differential or any other kind of differential, it is essential to ensure that it is installed correctly and that the bearing preload is set to the proper specifications.

The bearing preload setting is critical because it ensures that the bearings are tightened enough to prevent excessive play in the differential, but not so tight that they experience excessive wear or damage. If the bearing preload is set too loose, the differential will experience excessive play, leading to damage and eventually failure. If the preload is set too tight, the bearings will experience excessive wear and damage, leading to premature failure.

Similarly, proper differential fitting is critical because it ensures that the differential is properly aligned and secured in the gearbox. This helps to ensure that power is transmitted smoothly and efficiently from the engine to the wheels, without excessive wear or damage to the differential or other components.

When installing a gripper plate differential or any other kind of differential, it is important to follow the manufacturer's instructions carefully and to use the proper tools and procedures. This will help to ensure that the differential is properly installed and that the bearing preload is set to the correct specifications.

In addition to proper installation and bearing preload setting, it is also important to maintain the differential and gearbox regularly. This includes checking the fluid level and condition, inspecting the components for wear or damage, and replacing any worn or damaged components as needed.

By following these guidelines, vehicle owners can help to ensure that their differentials and gearboxes are properly installed and maintained, helping to prevent premature wear, damage, and failure. Whether installing a gripper plate differential or any other kind of differential, it is essential to take the time to do the job right, using the proper tools and procedures and following the manufacturer's instructions carefully.